全站搜索

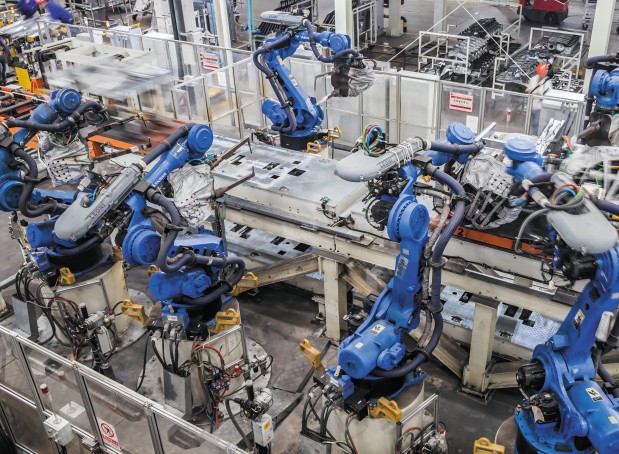

Robotic application solutions

Guangzhou ZSROBOT Intelligent Equipment Co., Ltd. is one of the largest automotive intelligent equipment technology R&D and manufacturing companies in China. For more than 10 years since its establishment, it has been deeply involved in the automotive industry. It can undertake all the fully automatic intelligent flexible production lines for stamping, handling, welding, assembly, gluing and other processes in the manufacturing process of white body, seat and frame. It has been committed to providing advanced intelligent, information-based, safe and reliable production equipment for major automobile factories such as Toyota, GAC Passenger Cars, Honda, Fiat, Great Wall Motors, Geely Automobile, BYD, and their affiliated parts manufacturers, and can realize the localization of various automatic production lines.

In the field of automotive intelligent manufacturing, it has accumulated a large number of innovative technical achievements and mature project experience, and has comprehensive capabilities from process planning, whole line layout, style formulation, 3D design, 3D dynamic simulation to drawing design and offline program output.