全站搜索

Furniture industry

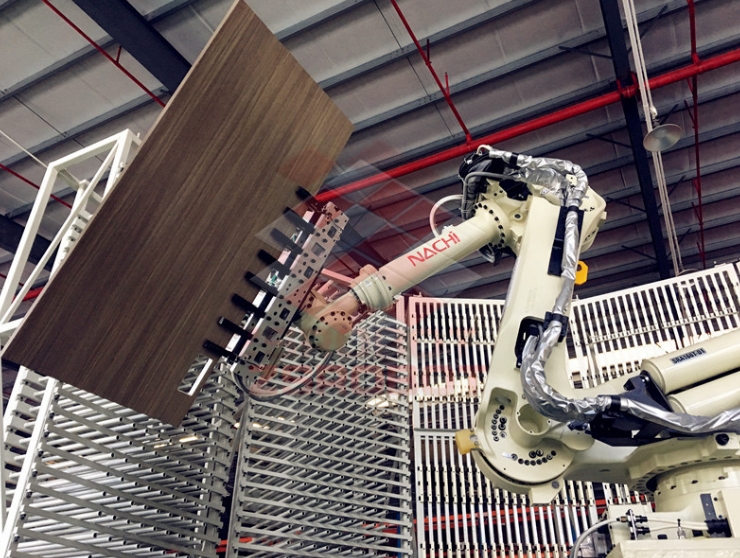

Robotic application solutions

The hardware part of the complete set of customized furniture industry includes cutting equipment, multi-axis handling robots, edge banding rotary line system, power transmission line, gantry gripper, six-sided drilling equipment, automatic sorting system, etc., which are controlled by the master control system and intelligent software to realize automated production.

The intelligent furniture industry is mainly based on unmanned factories, creating industrial production lines, integrating cutting, edge banding, drilling, sorting, packaging and other processes, so as to realize unmanned factory production mode.

Furniture video case